We understand the importance of selecting the correct vibration isolation solution for your impact machinery and the environment it operates in.

Vibration Control

Vibration isolation of impact machinery is crucial to minimise the transmission of vibrations

Generated by the machinery to the surrounding structure and to reduce the negative effects of those vibrations.

Impact machinery, such as presses can produce high-intensity vibrations that can lead to equipment damage, noise, and structural issues if not properly isolated.

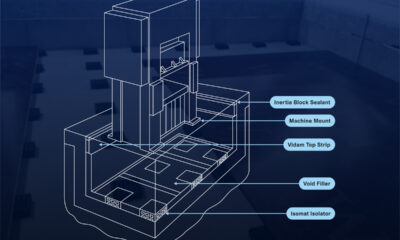

Farrat Isolated Foundations are used in many applications to ensure the operating conditions are controlled to within equipment specifications, to maximise productivity and to conform to H&S and local authority requirements.

Farrat offer several strategies to combat vibration isolation of impact machinery:

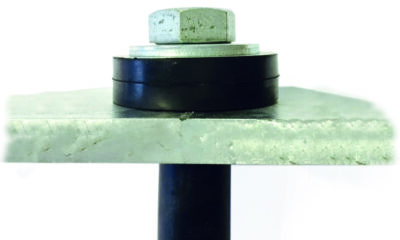

Resilient mounts, also known as vibration isolators or shock mounts, are commonly used to isolate impact machinery. These mounts are typically made of elastomeric materials, such as rubber or neoprene, which absorb and dissipate vibrations. Resilient mounts are installed between the machinery and its foundation or support structure, effectively decoupling the machinery from the surrounding environment and reducing vibration transmission.

Active vibration control systems can be employed to actively counteract the vibrations generated by impact machinery. These systems use sensors to detect vibrations and actuators to generate counteractive forces that reduce the impact of vibrations. Active vibration control systems can be particularly effective in reducing the impact of impact machinery vibrations.

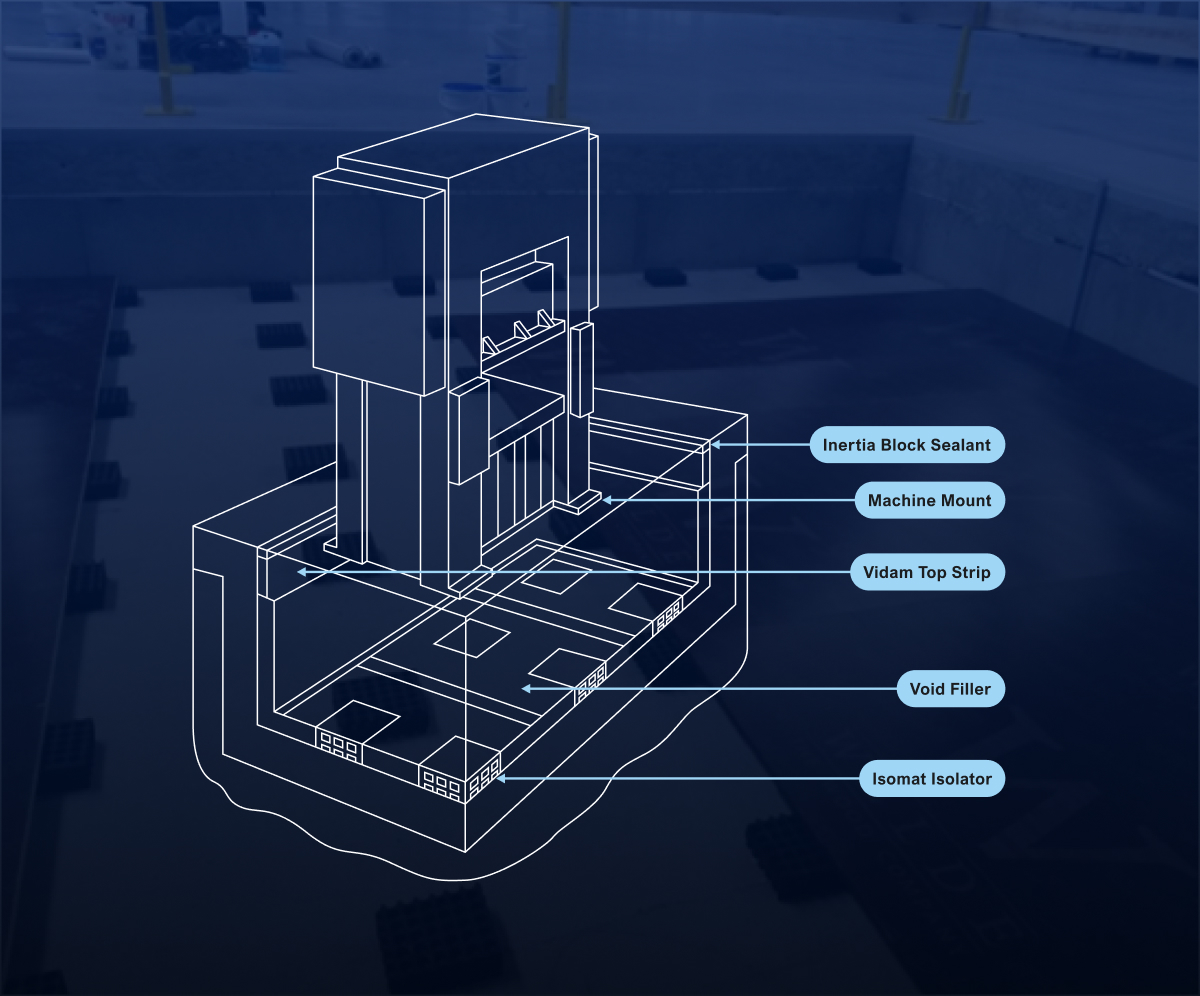

Inertia bases are heavy, rigid platforms or foundations that are specifically designed to support impact machinery. The mass and stiffness of the inertia base help absorb and dampen vibrations, preventing them from propagating to the surrounding structure. Inertia bases are typically made of concrete or steel and are separated from the main building structure using resilient mounts or other vibration isolation techniques.

The design of the machinery foundation plays a crucial role in vibration isolation. The foundation should be designed to withstand the impact forces and vibrations generated by the machinery. Incorporating techniques such as adding mass, utilising vibration-damping materials, or introducing isolation joints can help to reduce vibration transmission to the building structure.

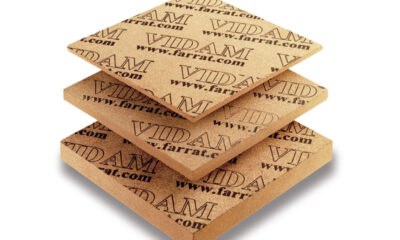

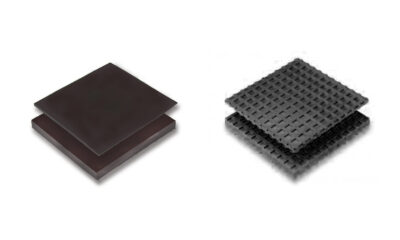

Damping materials, such as viscoelastic pads or coatings, can be applied to the machinery or its components to absorb and dissipate vibrations. These materials help reduce the resonant frequencies and dampen the impact vibrations, effectively isolating the machinery from the surrounding structure.

In some cases, structural modifications may be required to improve vibration isolation. This can include adding additional supports, braces, or stiffening elements to reduce the dynamic response of the structure to impact vibrations. Reinforcing critical structural elements can also help mitigate the effects of vibrations.

Anti-vibration materials are used on machinery to reduce or dampen the transmission of vibrations

Caused by various sources, such as machinery, traffic, or nearby construction.

Our range of materials help protect the structure, its occupants and neighbours from the negative effects of vibration.

Common anti-vibration materials include:

Elastomeric isolators, also known as vibration isolators or mounts, are widely used to isolate and reduce vibrations. These isolators consist of rubber or elastomeric materials that absorb and dissipate vibrations. They are often used to isolate equipment, such as HVAC systems, generators, or heavy machinery, from the building structure. We use a combination of materials designed and manufactured by our inhouse team of specialists. We actively encourage our customers to engage with us as early as possible in the design process so we can add value gained from decades of engineering experience built in numerous environments and locations.

Spring mounts are another type of vibration isolators that use metal springs to isolate vibrations. These mounts are effective in reducing low-frequency vibrations and are commonly used for heavy equipment or machinery.

Vibration dampening pads are typically made of rubber or foam materials and are used to absorb and reduce vibrations. These pads are commonly placed between equipment and the building structure to minimise vibration transmission.

Some machine tools, including, grinders, suffer from chatter instability due to lack of structural damping. As a solution to this common problem, we offer an extremely effective way of adding damping to the machine in the form of tuned mass damper to suppress all manner of resonant vibration problems.

Viscoelastic materials, such as viscoelastic polymers or composite materials, exhibit both viscous and elastic properties. They are capable of dissipating and absorbing vibrations, making them suitable for reducing structural vibrations in buildings.

Active vibration control systems use sensors and actuators to actively monitor and counteract vibrations in real-time. These systems can be employed in critical structures to minimize the effects of vibrations.

Our engineering capabilities

Proper maintenance of impact machinery is crucial for ensuring its optimal performance and minimizing vibration issues. Regular inspections, alignments, lubrication, and balancing of rotating components can help identify and address any potential vibration problems before they escalate.

We recommend an initial consultation with vibration control specialists, structural engineers, or machinery manufacturers to develop an effective vibration isolation plan tailored to the specific requirements of the impact machinery and the surrounding structure. They can provide expertise in assessing vibration characteristics, selecting appropriate isolation techniques, and ensuring compliance with relevant safety standards.

Latest case studies

Challenge our engineers

Contact us now for an initial consultation.