A DAC 150 Cupper Press was installed in a can-making factory in Switzerland next to a noise and vibration-sensitive pharmaceutical factory and near to residential dwellings. The ground below the factory was rock, through which vibration can travel quickly and long distances.

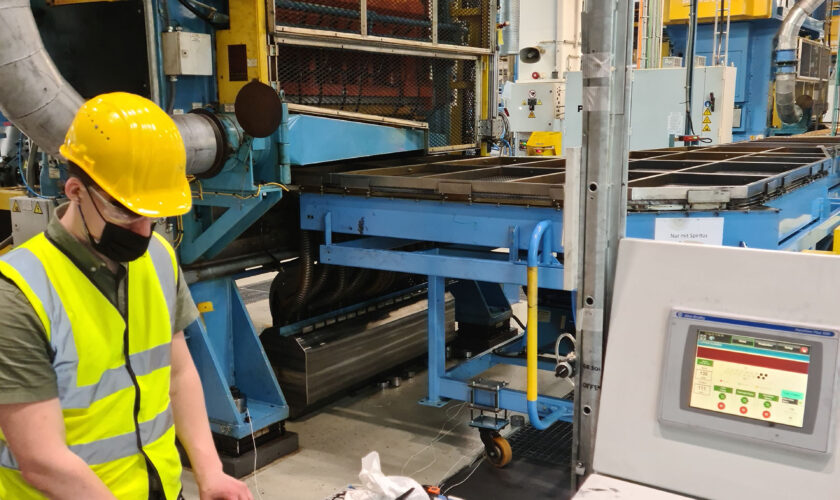

Cupper Presses are an integral part of can manufacturing, used to stamp cylindrical cups from rolls of aluminium or steel. This action generates vertical ‘shock’ excitations at frequencies determined by the speed of the machine.

The Cupper Press was installed on a 4m deep concrete inertia block supported by spring elements and viscos-dampers designed and supplied by another manufacturer. Even on coil springs the press was affecting the neighbouring factory so the springs were softened, ending up at a system natural frequency of 1.25 Hz.