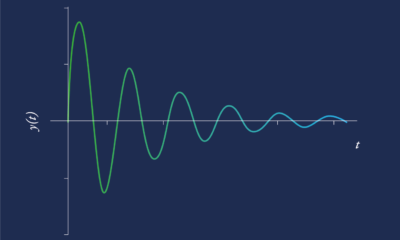

When commissioning new equipment such as a press, it is essential to design an appropriate base or foundation to limit transmission of impact forces to the surrounding area. Failure to do this can result in vibration being felt in office areas or by the occupants of neighbouring buildings. Our team of applications engineers provide expert advise on selecting the right vibration isolation system for your equipment to achieve the optimum level of isolation. PAT & FAT. Our consultancy services assist sellers and buyers with Pre and Final acceptance tests, of new or refurbished equipment, for complete peace of mind. Installing complex isolation systems can be a challenge for someone installing them for the first time.

Latest Case Studies

Most commonly raised vibration queries

The answer largely hinges on the mass of the equipment in question. For instance, a heavier piece of equipment, such as a mechanical press, would require a full-size foundation with concrete inertia block. On the other hand, a comparatively lighter piece of equipment like a compressor can effectively use specialised mounts or anti-vibration pads. Our engineers can assist you in selecting the right system for your equipment.

Conducting vibration measurements is essential to evaluate the appropriateness of a new equipment location and confirm that it won’t introduce any additional vibration sources.

Pre and post-installation surveys provide comprehensive reassurance to the engineering, projects, and operations teams by verifying that the installed isolation system is operating according to the design. Our engineering team can arrange these surveys. For more information, please get in touch here.

Certainly, we can arrange for a Pre-Acceptance Test (PAT), which proves highly beneficial for buyers of capital equipment, such as a grinding machine. These tests, conducted at the manufacturer’s site in conjunction with the buyer’s acceptance tests, specifically aim to identify any abnormal vibrations that could potentially impact product quality. Any sources of vibrations identified, along with our recommendations, will be detailed in a comprehensive report.

Factory Acceptance Test (FAT) tests are similar in nature to PAT and are carried out at the customer’s site. The emphasis of these tests is to ensure that the transit of the machine and its installation on the new location do not bring about any new potential vibration sources.

We have the capability to assess and analyse the operational dynamics of machinery using advanced vibration analysis tools and software. We extend these services to numerous companies globally, enabling them to optimise the performance of their machinery.

Choosing an appropriate levelling mount is primarily influenced by the type of equipment, its mass, and the desired level of precision. Explore our selection of machine mounts. For assistance in making the right choice, reach out to our engineering team.

Farrat is well-equipped to aid clients in complying with regulations and implementing measures to manage the transmission of vibrations. Our engineers can support you in conducting vibration investigations, analyses, design and implementation of mitigating measures.

Our products & services

Contact us

Please select the best route to suit your requirements. Whether you require technical help or you’d like to make a general enquiry. The team are here and always ready to support you.

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00