OEE is an important parameter for the manufacturing industry, unwanted vibration is one of many factors that can negatively impact productivity. Our application engineering team work closely with manufacturers to identify the problematic frequencies and advises ways to mitigate them. Maintenance or shutdown is an ideal time to investigate ongoing issues with plant and machinery.

Latest Case Studies

Most commonly raised vibration queries

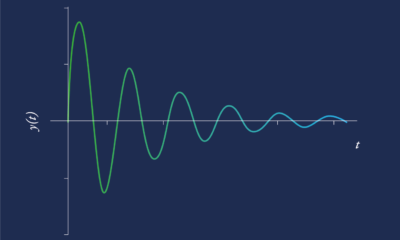

Vibrations from equipment can be managed through different methods, such as incorporating damping elements, using isolation mounts, employing isolated foundations, or simply adjusting operational parameters. The choice of method depends on variables such as the type of equipment, its mass, operating frequency, and operating environment. Contact our engineers for guidance.

To control press movement, employ anti-vibration pads to dampen sudden impacts and vibrations, thereby reducing equipment stress. Optimise the foundation design for stability and vibration absorption, which can significantly decrease press movement. Consult with equipment manufacturers or specialists such as Farrat for insights into tailored measures and solutions for your machinery.

There are several methods available to manage the transmission of vibration from equipment to the surrounding area. The choice of the appropriate system relies on factors such as the type of equipment, its mass, operating frequency, dynamic loads, and the operating environment. Various options are at your disposal, including specialised mounts or pads created to absorb and dampen vibrations. These can be positioned between the machine and its foundation or between its components, and isolated foundations or floating floors beneath the machine can reduce direct contact with the floor, thereby minimising vibration transmission. For custom solutions tailored to your machinery’s specific characteristics, you can seek advice from Farrat.

We use modal analysis technique to identify and address potential structural issues before they lead to operational problems or failures. Regular modal analysis as part of a predictive maintenance program can contribute to the early detection of structural issues, promoting the longevity and reliability of the machine.

Our products & services

Contact us

Please select the best route to suit your requirements. Whether you require technical help or you’d like to make a general enquiry. The team are here and always ready to support you.

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00