Our solutions are used for stamping, inspection, drawing presses & bodymakers.

Equipment Lifecycle

Our engineering-driven solutions offer specialised expertise tailored to address the diverse stages throughout the lifecycle of equipment.

Our products & services

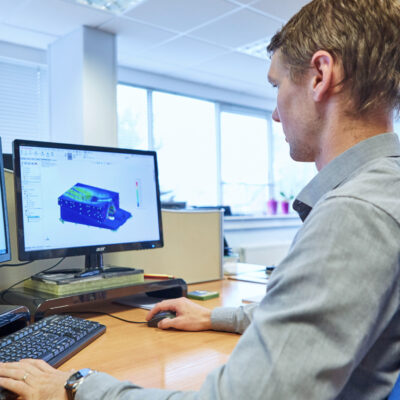

Consultancy

Farrat offer a wide range of analysis, design and consultancy services, working on-site to find the right solution.

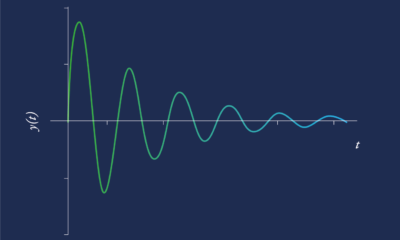

Industrial Vibration Control

We understand the importance of selecting the correct vibration isolation solution for your impact machinery and the environment it operates in.

Machine Mounts

We have been designing and manufacturing high performance Machine Mounts and Machinery installation systems since the 1959.

Contact us

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00

General Enquiry

Please provide the following: