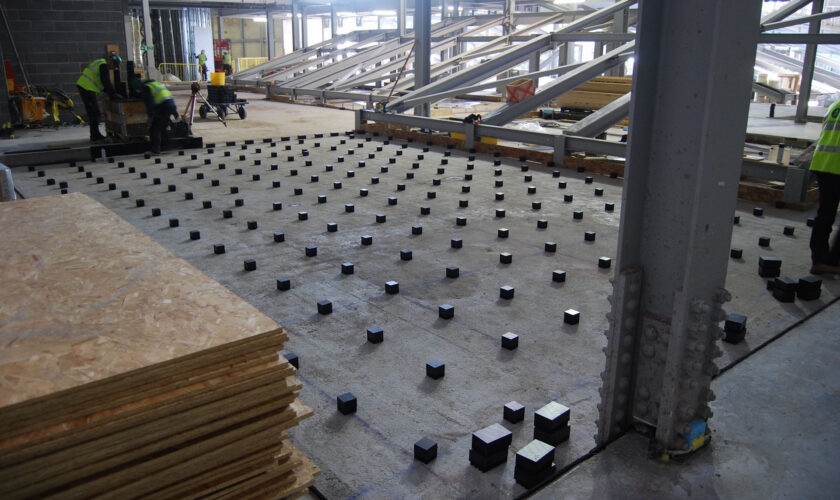

The Rock is Bury’s premier shopping and entertainment destination, a state of the art retail and residential development designed to rejuvenate Bury town centre. Consisting of 1700 ultra comfortable stadium seats spread

across ten screens, The Rock’s VUE Cinema features the latest in cinema innovation, right down to the bits you can’t see,

including its innovative acoustic isolation system.

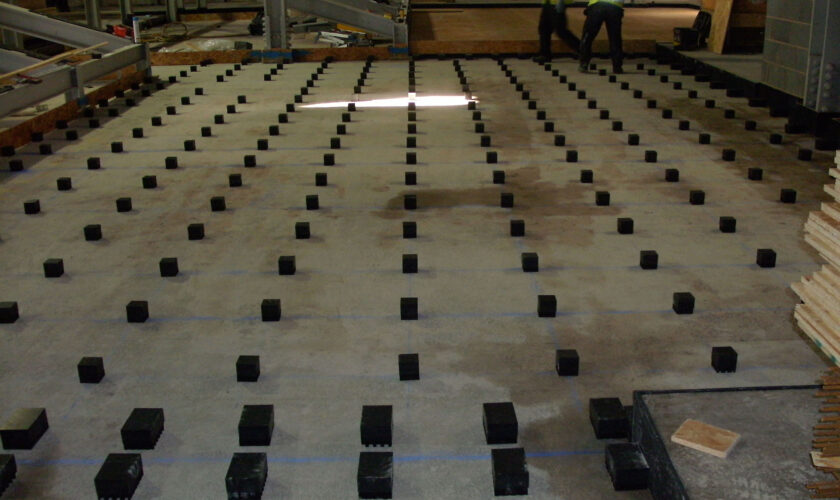

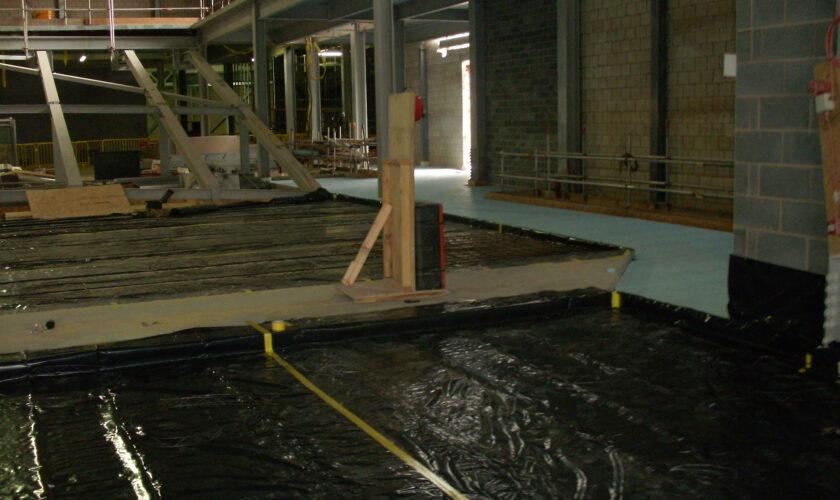

There were 2 key elements to this challenge – the cinema would require a box in box system with the internal acoustic walls installed around the perimeter of the floating floors. Each screen was a different size and shape meaning that each would require bespoke design. Meanwhile the bowling alley was a more complex element as the details of the exact equipment required were not known about until later on in the process. The design of the isolators and the slab reinforcement would need to tie up with the varying load characteristics of the equipment geared around a light load at the user end of the lanes combined with a heavy load at the pinsetter end of the lanes.