This unique project was geared around the creation of a floating floor for a private individual who wished to convert a room in her prestigious apartment into a music room to enable her to indulge in her passion for playing the piano. There were neighbouring apartments above, below and next door to this room so effective isolation was imperative. The room was not very big so retaining as much space as possible was important. The acoustic consultant designed a box in box system comprising of an acoustic ceiling, walls and floors and recommended Farrat for the supply of an acoustic floor.

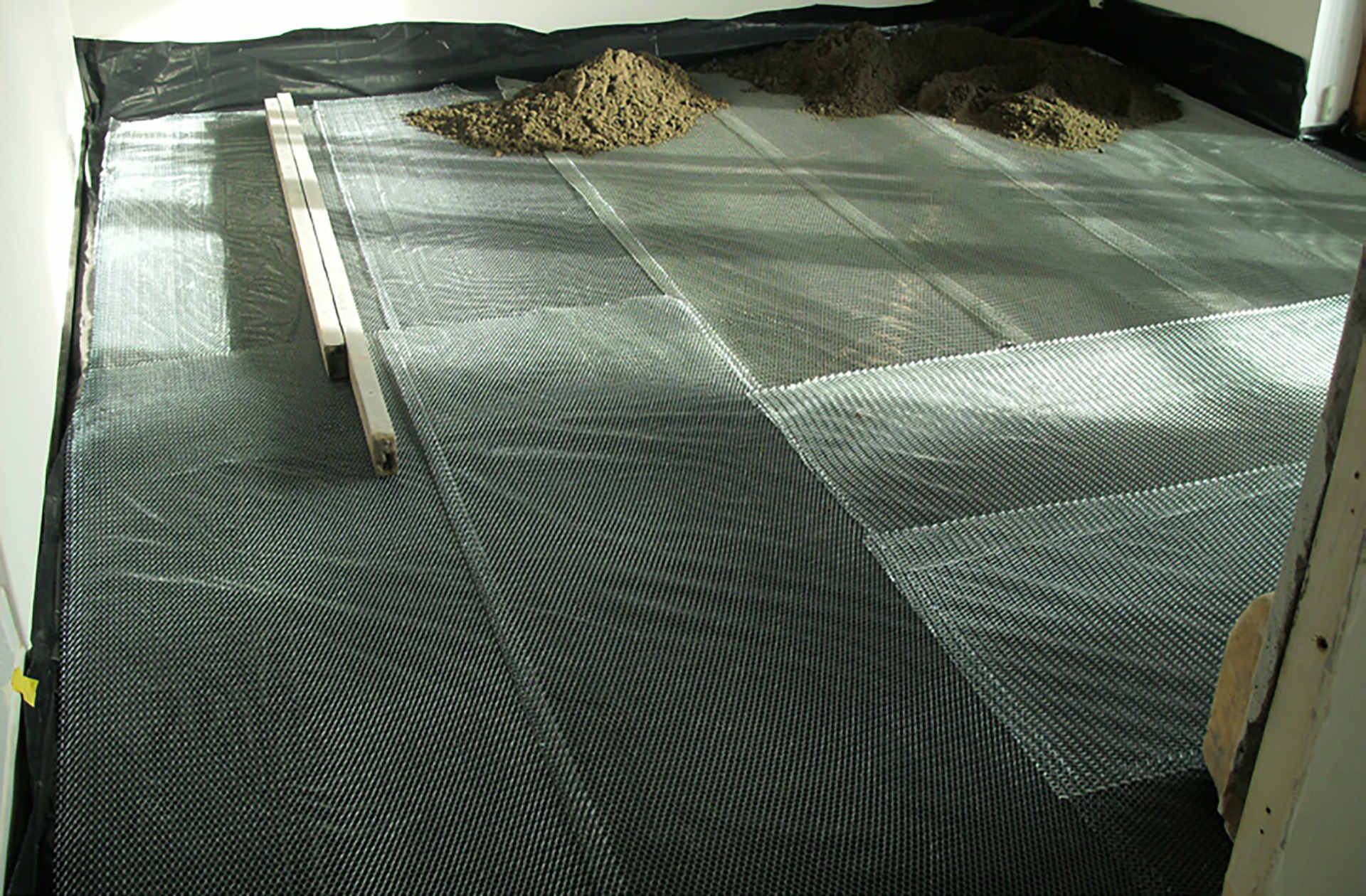

Farrat worked in close partnership with the architect to develop a bespoke workable solution. Although there was a height constraint of 100mm the objective was to use as much mass as possible in the floating slab. Access constraints and the size of the room meant that a concrete slab was out of the question but a screed slab would provide the highest amount of mass in this case.