Farrat Isomat pads effectively used to isolate ground-borne vibration at General Electric’s (GE) manufacturing plant.

Isomat system provides full isolation for 300 tonne roll grinder

Project Overview

The Challenge

Herkules roll grinding machines are well-known throughout the world for their excellent performance in terms of precision, speed and efficiency. The combination of an ultra-fast control and state-of-the-art measuring, allows for high-speed correction grinding, suited to that required by General Electric (GE) at their manufacturing plant in Rugby, which grinds shafts of special electrical drives for the Ministry of Defense (MOD).

When planning the plant layout, GE decided that the Herkules roll grinder would need to be situated adjacent to several presses, however this would increase the ground-borne vibration levels and have a severe impact on operational performance. The roll grinder foundations would therefore need to be isolated, to prevent vibrations from entering the inertia block.

The Solution

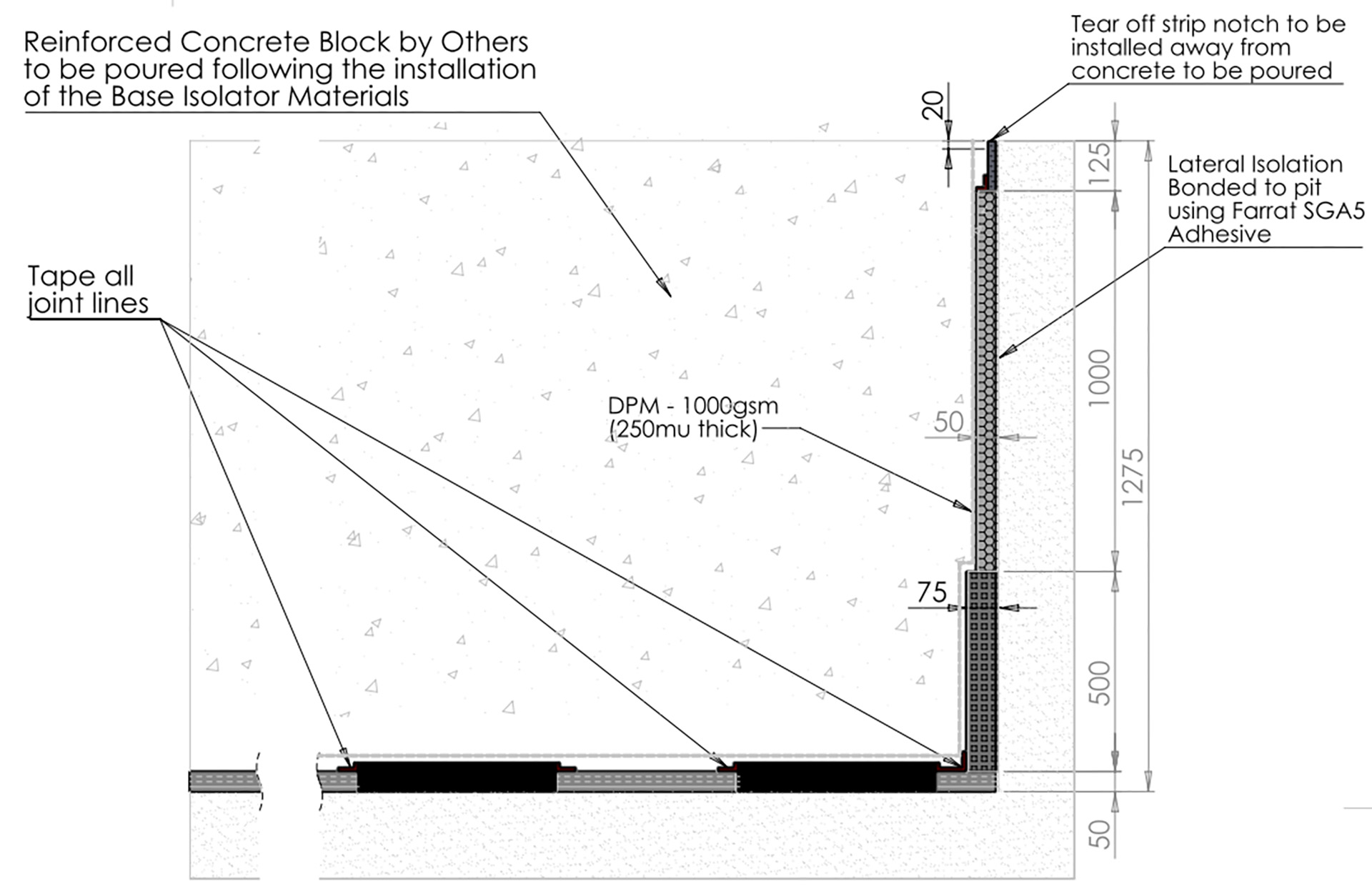

Farrat were approached by a specialist Structural Engineer for the specification of the roll grinder foundations. The combined machine / inertia block mass equated to over 300 tonne, so Farrat recommended a Full Isolation Isomat system, which would isolate both the base of the inertia block and the foundation walls.

Farrat supplied 40 Isomat Pads, 500mm x 500mm x 50mm thick and used a 45 hardness Chloroprene rubber compound, to achieve an effective compromise between vibration isolation and damping. Isomat pads deliver highly-predictable performance characteristics, over many years of service, and Chloroprene has high-elasticity, moderate-damping and good oil and chemical resistance properties. Farrat’s Isofoam material was then installed on the walls, as this material provides excellent isolation where sensitive machinery is installed.

The solution provided a dynamic natural frequency of 8.3Hz, which was sufficient to provide the required isolation and also provided excellent stability – due to the grinder head mass traversing. This maximised overall equipment effectiveness (OEE) to ensure product quality.

Related Projects

Challenge our engineers

Contact us now for an initial consultation.