This project was part of a £193 million development scheme designed to combine the new library and the repertory theatre (REP) in Birmingham city centre, thereby creating a unique centre for knowledge, learning and culture. Scheduled to open at the end of 2013, the main library building is a nine-storey structure. Floor to floor heights vary and are up to eight metres in the archive areas with the highest loaded floors high up the structure. Within the library building is a studio theatre, which is a steel framed structure, acoustically isolated from the rest of the building.

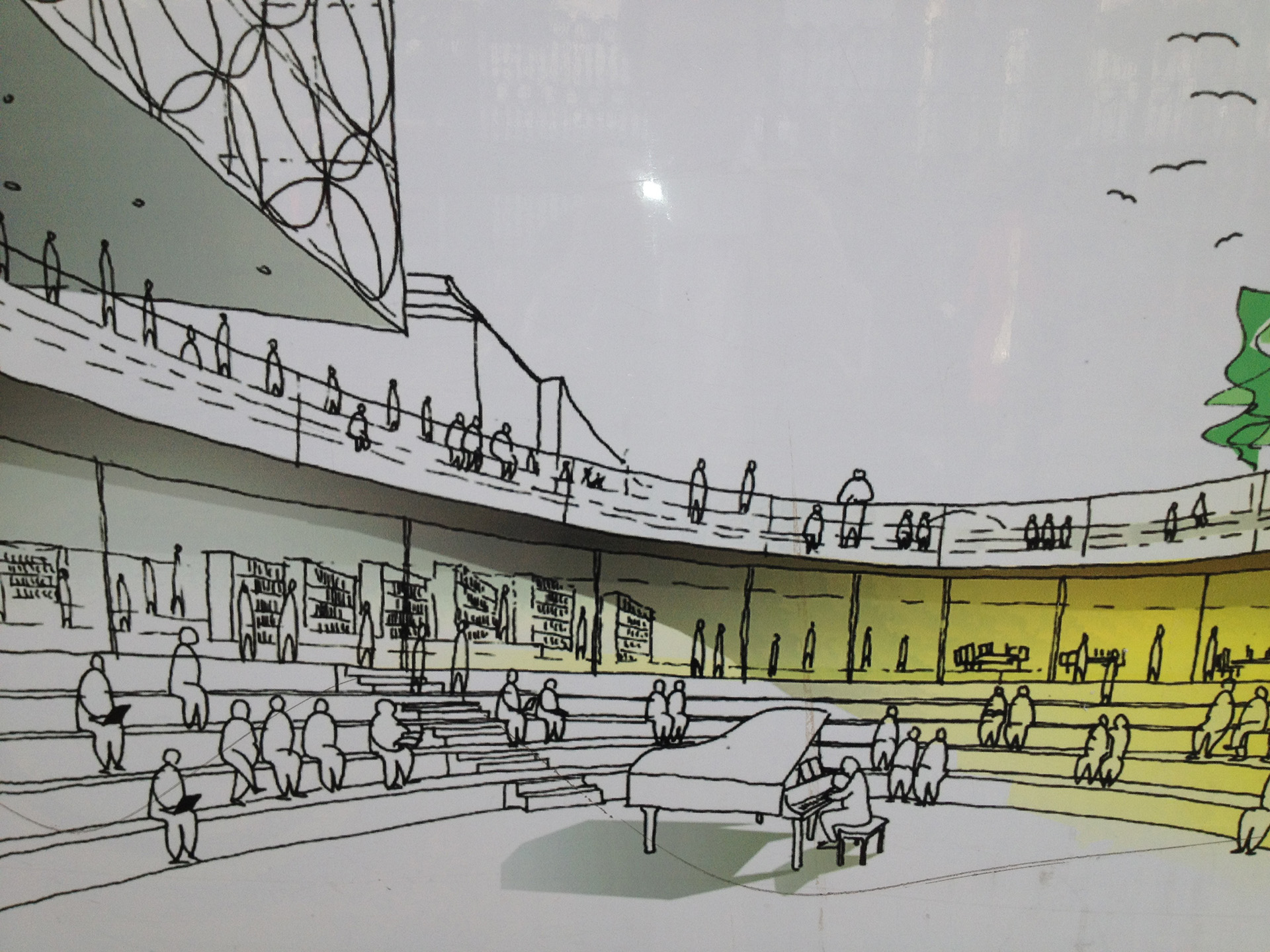

As well as being close to the Monument Lane railway tunnel, the site is also located adjacent to the International Convention Centre (ICC) and a number of residential buildings meaning that there were several acoustic challenges to overcome. In addition some areas of the development would be shared between the Library and the REP (e.g. a new studio theatre, restaurant, shops, foyer, rehearsal rooms and workshops). The REP theatre and the Library will be joined together and will share a number of facilities including a foyer, cafe restaurant, meeting rooms, rehearsal rooms and a new 350 seat auditorium to complement the theatre’s two existing auditoria.

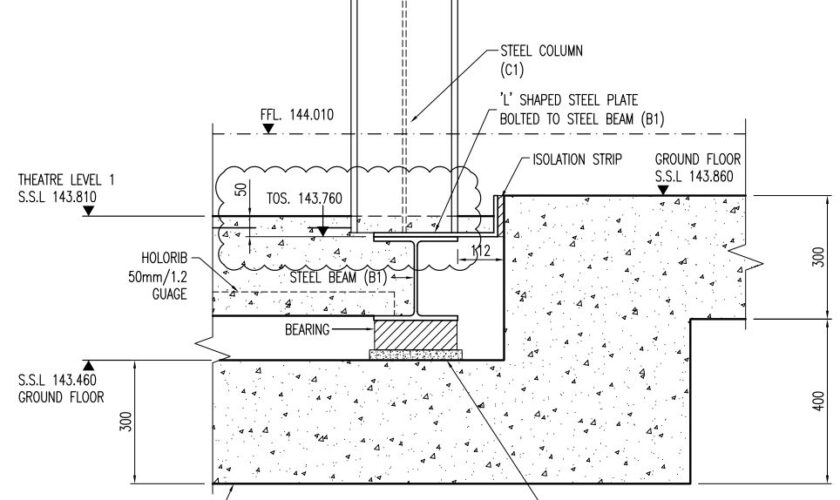

To achieve this, a ‘box-in-box’ construction was designed in conjunction with the Architect and the Structural Engineer. This was geared around specific acoustic construction requirements for the floated concrete floors and the perimeter walls.