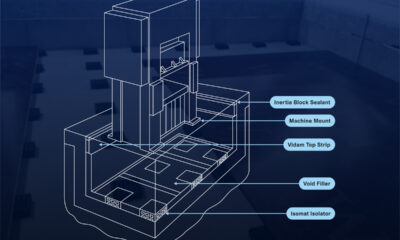

Farrat Isomounts provide a simple, economical and flexible solution to factory or plant room layout planning, enabling easy installation and movement of machines without the need for bolting down or grouting.

Isomounts

Effective vertical and horizontal shock absorption, vibration isolation and damping as well as easy and precise levelling

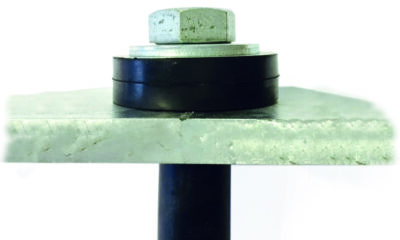

Farrat Isomounts have been designed to provide effective vertical and horizontal shock absorption, vibration isolation and damping as well as easy and precise levelling, for a wide variety of machinery and equipment.

Farrat Isomounts provide a simple, economical and flexible solution to factory or plant room layout planning, enabling easy installation and movement of machines without the need for bolting down or grouting.

Farrat Isomounts

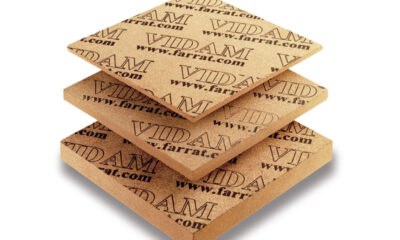

Our Isomounts are manufactured from the highest quality zinc plated steel and Farrat NBR high damping, oil resistant rubber.

The design has been continuously improved to ensure long-term durability against mechanical degradation and chemical corrosion. This is proven with thousands of worldwide industrial applications.

Load range from 150kg up to 5,000kg per mount.

Isomounts Size Range

| Ref | Max Load (kg) | D1 (mm) | D2 (mm) | H1 (mm) | H2 (mm) | Vertical Adjustment (mm) |

Standard Rubber (IRHD A) | Vertical Spring Constant (kN/mm) | Horizontal Spring Constant (kN/mm) | Damping (C/Cc) |

Dynamic to Static Modulus |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0-70 | 150 | 50 | 36 | 21 | 30 | 9 | -70 | 1.2 | 0.4 | 0.09 | 2.4 |

| 1-80 | 500 | 78 | 60 | 32 | 44 | 12 | -80 | 3.3 | 1.2 | 0.09 | 2.4 |

| 2-80 | 1,200 | 118 | 100 | 39 | 55 | 16 | -80 | 7 | 2.5 | 0.09 | 2.4 |

| 2H-80 | 1,500 | 120 | 100 | 55 | 70 | 15 | -80 | 7 | 2.5 | 0.09 | 2.4 |

| 3HM-80 | 3,000 | 160 | 140 | 55 | 75 | 20 | -80 | 17 | 6 | 0.09 | 2.4 |

| 35-80 | 4,000 | 200 | 170 | 55 | 75 | 20 | -80 | 21 | 7 | 0.09 | 2.4 |

| 4-80 | 5,000 | 228 | 200 | 55 | 75 | 20 | -80 | 26 | 10 | 0.09 | 2.4 |

| Unit | Hex Head (H) | Hex Stud (SH) |

|---|---|---|

| 0-70 | M10x1.5 | - |

| 1-80 | M10x1.5 M12x1.75 |

- |

| 2-80 | M12x1.75 M16x2.0 |

M16x1.5 |

| 2H-80 | - | M16x1.5 |

| 3HM-80 | M20x1.5 | M20x1.5 |

| 35-80 | M20x1.5 M24x1.5 |

M20x1.5 M24x1.5 |

| 4-80 | M20x1.5 M24x1.5 |

M20x1.5 M24x1.5 |

| Style H | M10x1.5 | M12x1.75 | M16x2.0 | M20x1.5 | M24x1.5 |

|---|---|---|---|---|---|

| Length (mm) | 60 | 80 | 100 | 100 | 130 |

| Length (mm) |

80 | 100 | 150 | 150 | 150 |

| Length (mm) |

- | - | - | 250 | 200 |

| Spanner | 17A/F | 19A/F | 24A/F | 30A/F | 36A/F |

| Style SH | - | - | M16x1.5 | M20x1.5 | M24x1.5 |

|---|---|---|---|---|---|

| Length (mm) |

- | - | 100 | 170 | 170 |

| Length (mm) |

- | - | 120 | - | - |

| Spanner | - | - | 12A/F | 15A/F | 19A/AF |

Features & Benefits

- Vertical and horizontal shock and vibration isolation performance

- Improve performance, reduce wear and lower noise levels of machines

- Simple and economical machine installation

- High friction grip so machines do not move

- Factory layout flexibility (no bolting down or grouting)

- Heavy duty and durable design

- Manufactured from the highest quality materials

- Oil and chemical resistant

- Thousands of worldwide industrial applications

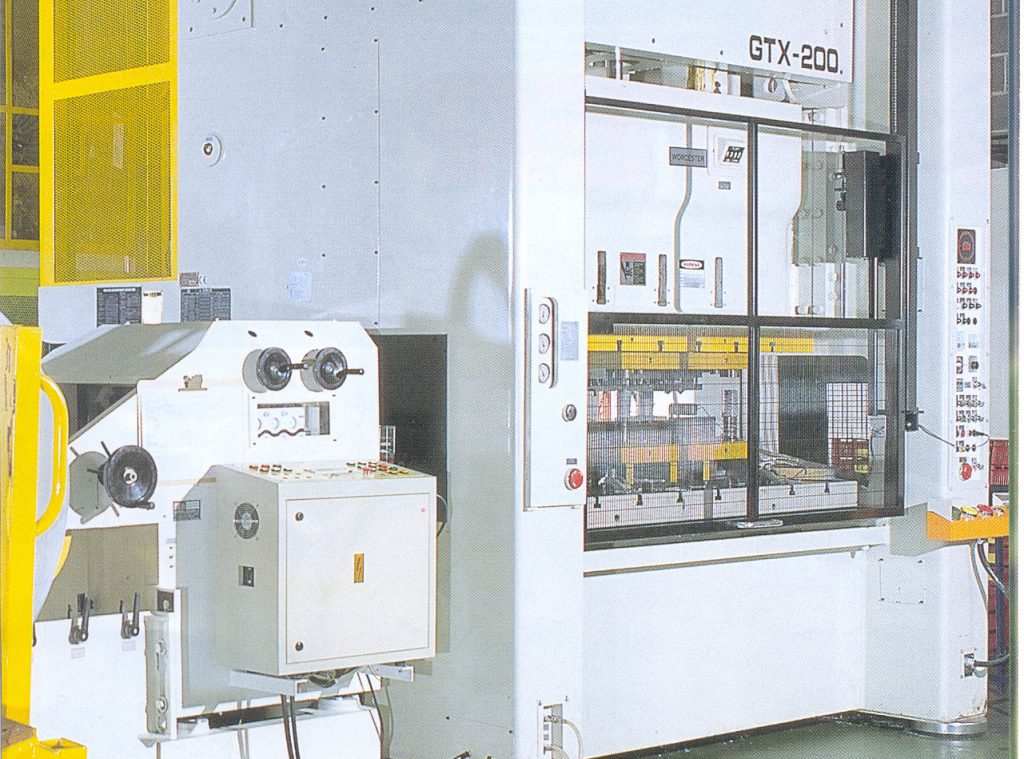

Machinery Applications

Injection Moulding machines, Presses, Forging, hydraulic and mechanical, Die-casting machines, Turret punching machines, Rubber machinery, Packaging machinery, Testing and Measuring machinery, Diesel generators, Hydraulic power packs, Compressors and Pump sets.

Contact us

Please select the best route to suit your requirements. Whether you require technical help or you’d like to make a general enquiry. The team are here and always ready to support you.

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00