Euston Square houses the headquarters of the Royal College of General Practitioners (RCGP). As part of a major £22 million refurbishment of the 10,000 sq ft of space at 30 Euston Square there would be a key requirement for building isolation for the building’s main lecture theatre situated in the basement. The objective was to control noise intrusion from re-radiated noise from underground trains coming into and going out of the nearby Euston Station.

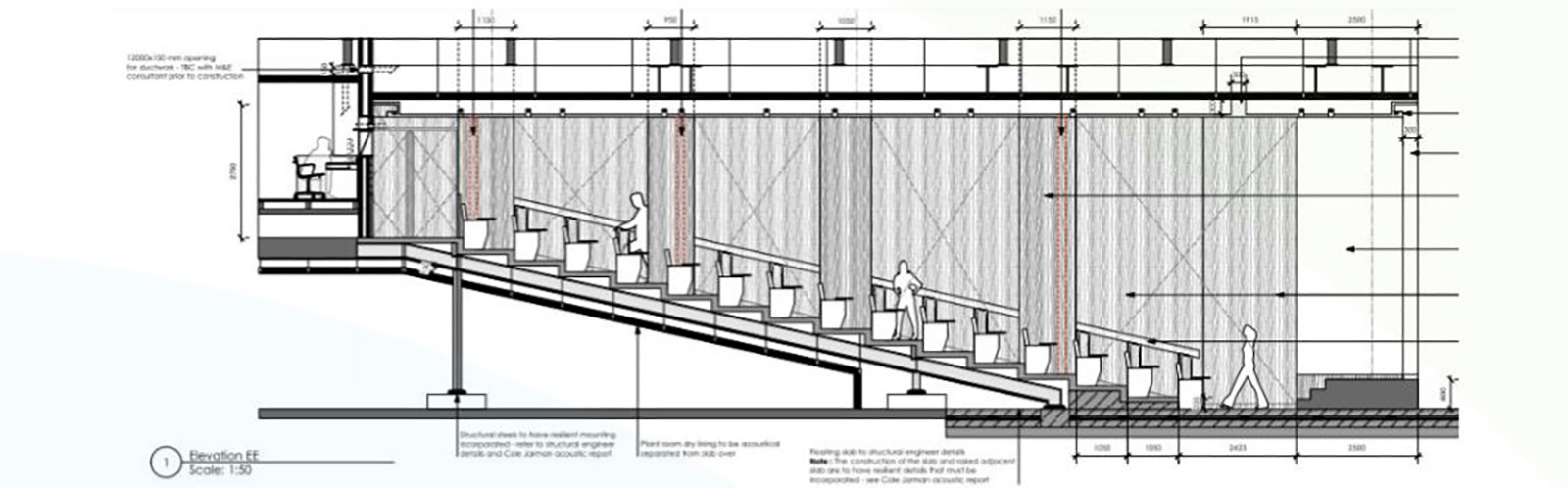

There were some particular challenges posed by virtue of the fact that the building is Grade II listed and structural changes were planned, as well as an internal fit-out to accommodate 350 employees of the college. The other key requirement would be to isolate the internal elements of the auditorium from the surrounding buildings including University College Hospital and University College London using a box-in-box type construction.

The floating floor itself would need to be designed to achieve not more than 12Hz which would provide around 96-98% isolation from the disturbing rail frequencies which peaked at around 100Hz.