Isolated Foundations (IFDs) either protect sensitive machinery from surrounding vibrations (passive isolation) or reduce vibrations and prevent them from migrating to the surrounding foundations (active isolation).

Isolated Foundation

How are Isolated Foundations constructed?

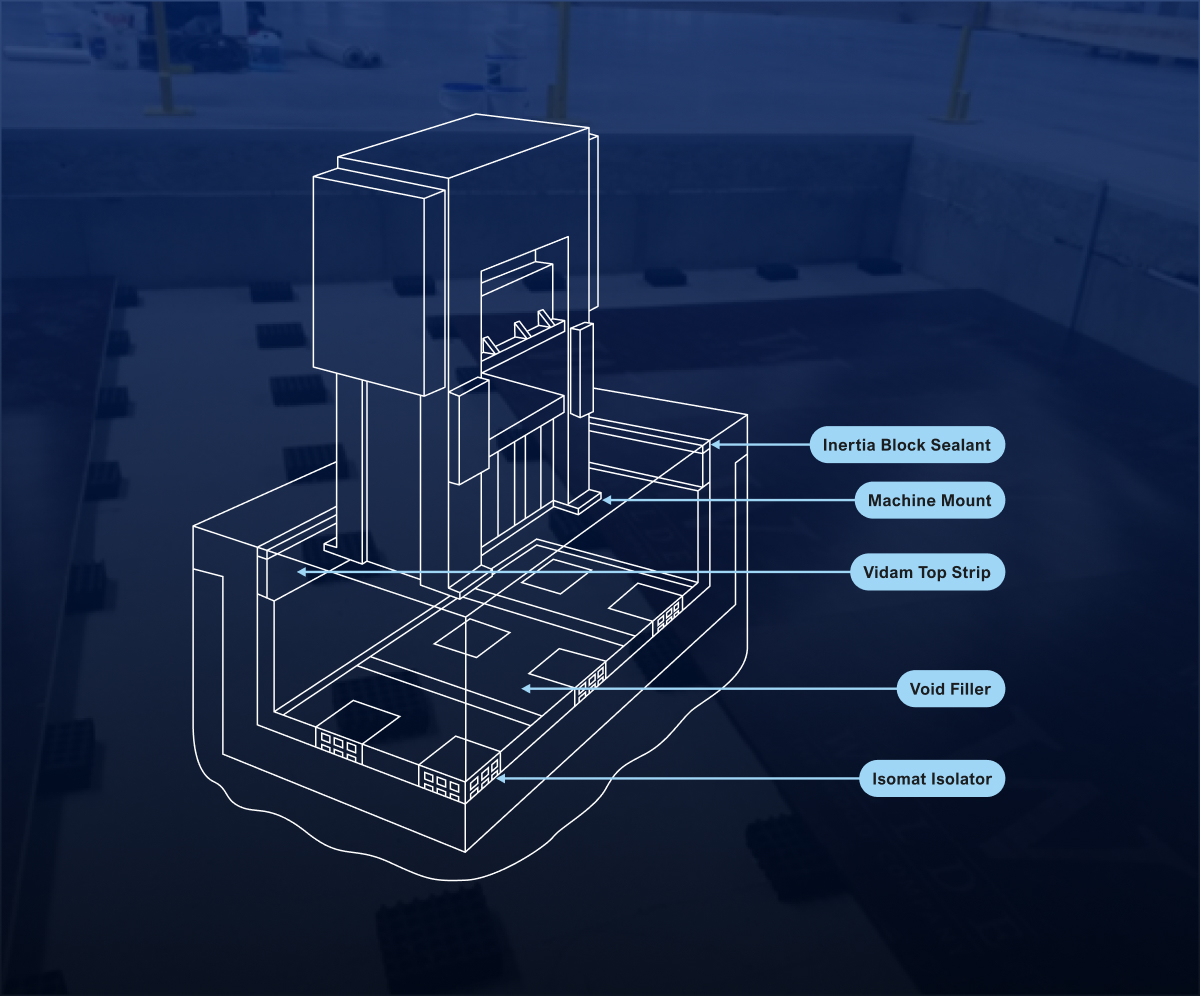

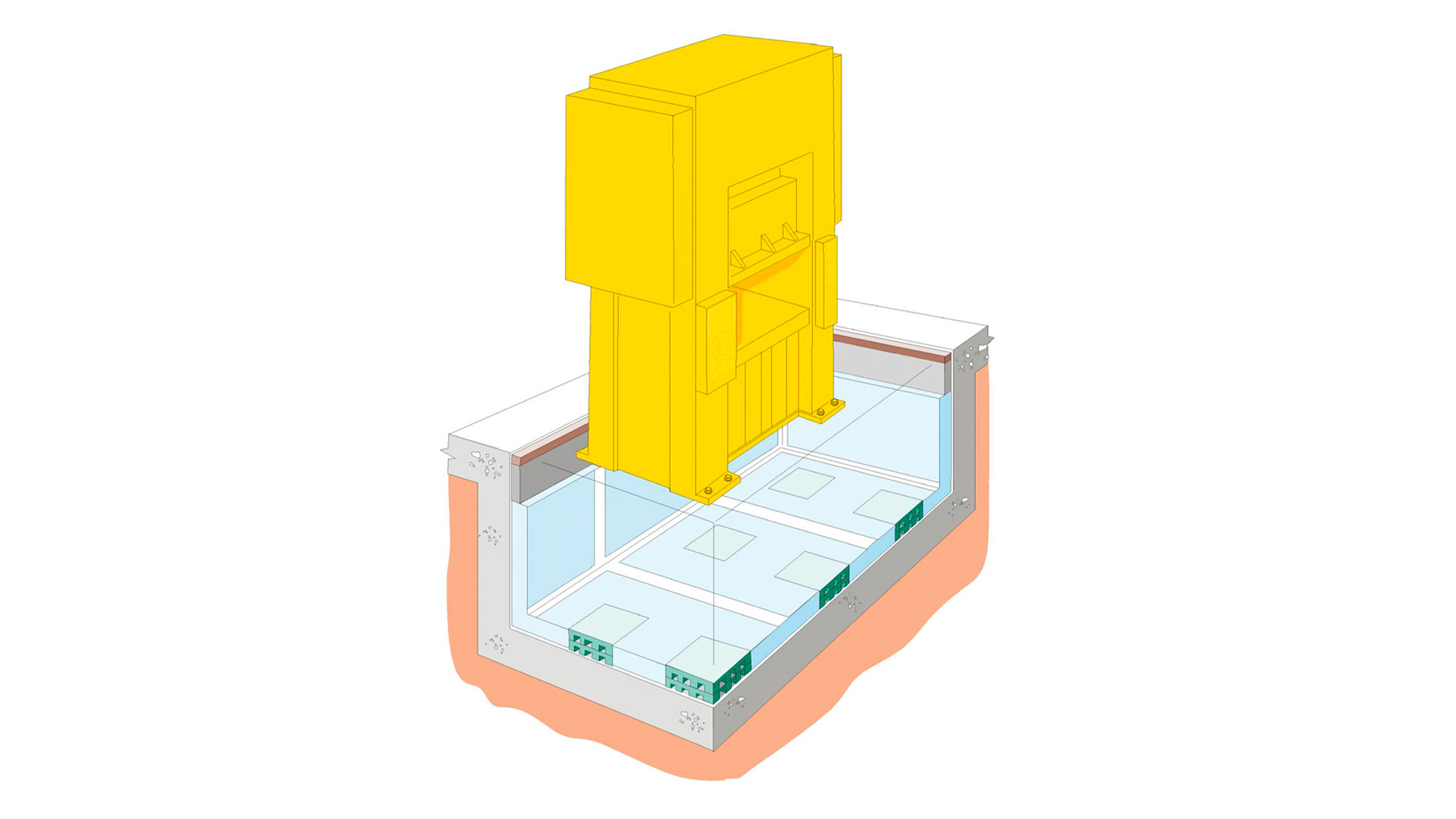

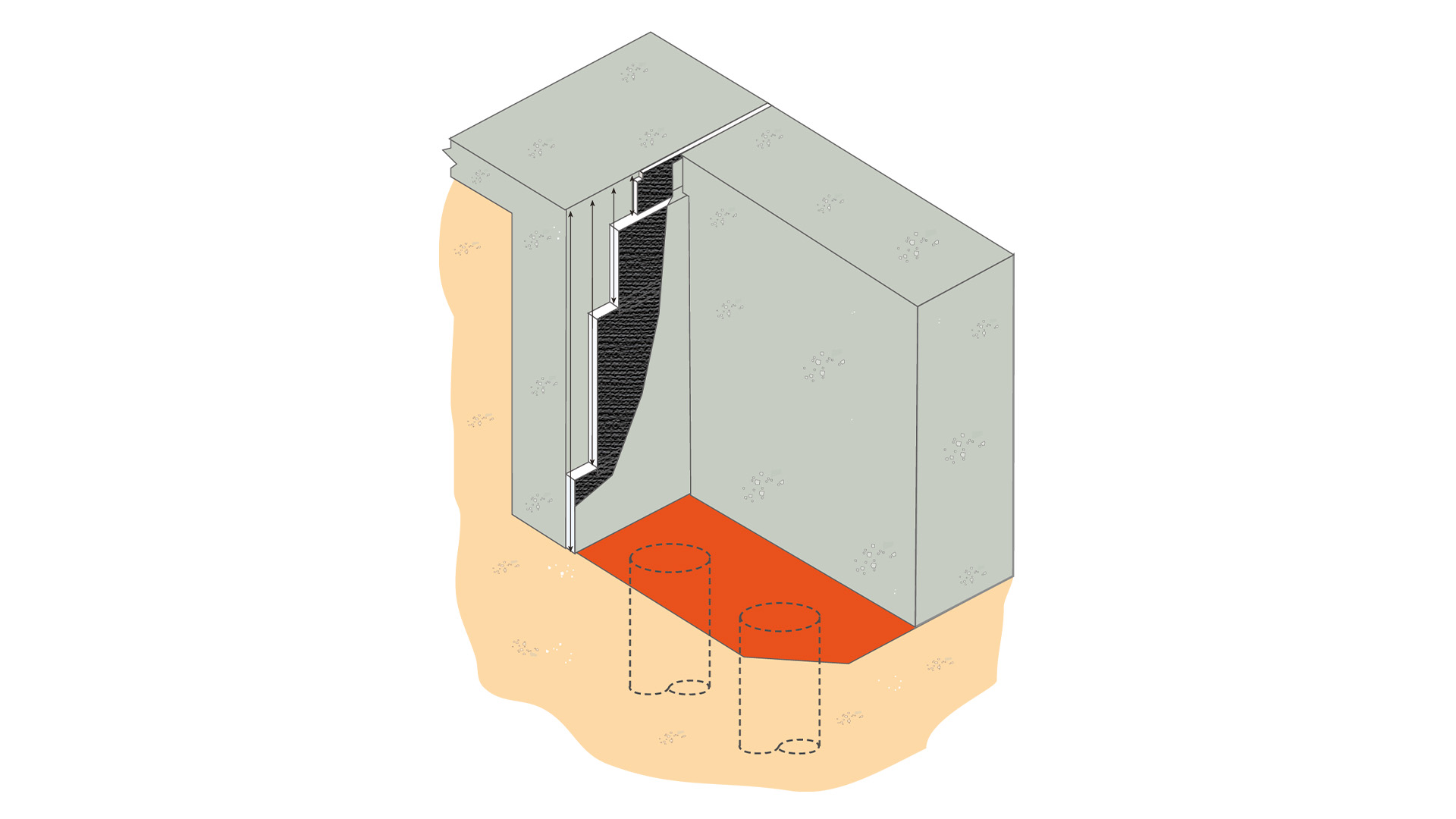

Farrat solutions comprise of a concrete inertia block, to which equipment or machinery is rigidly connected.

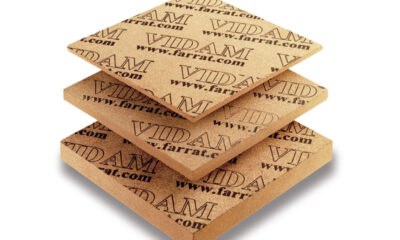

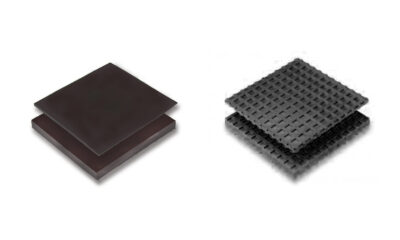

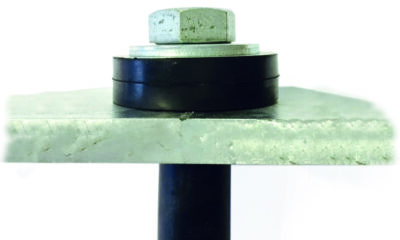

Specialist Vibration Isolating Material, provided by Farrat, surrounds the inertia block to prevent vibration from either entering or leaving, depending on the particular application.

What different configurations are there?

Although there are multiple variants, there are two main themes of isolation: full isolation and lateral isolation.

With full isolation, both the base and walls of the inertia block are surrounded with Vibration Isolating Material, whereas for lateral isolation, only the walls are surrounded.

How does the Vibration Isolating Material work?

There are specific material properties determined by specialist in-house test equipment at Farrat – that allow us to determine the transmissibility.

This is also affected by the exciting frequency, natural frequency, mass and the isolation efficiency given under load conditions, among other factors.

What does the inertia block do?

- The inertia block adds mass, which significantly reduces the vibration levels relative to the vibratory force. This is known as “mass damping’”

- The inertia block adds stiffness, thus maintaining alignment during changes in static and dynamic loads. This can be particularly beneficial for long-bed machinery, modular machines or high-precision equipment.

- The inertia block also reduces the centre of gravity (CoG), which can be very beneficial for equipment with a high CoG.

- Farrat can provide guidance when determining the Inertia block size for a particular application.

Typical Applications

- Printing Presses

- Cupping Presses

- Power Presses

- Roll Grinders

- Recycling Centres

- Forges

- Long-bed Machinery

- Metrology & Inspection

- CMM

- Water Turbines

- Pumps & Compressors

- Weaving Machines

- Large Machining Centres

- Oil & Gas

- Dynamic Test Rigs

- Manufacturing Facilities

Contact us

Please select the best route to suit your requirements. Whether you require technical help or you’d like to make a general enquiry. The team are here and always ready to support you.

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00