Farrat Levalators improve large, precision and long bed machinery performance by increasing alignment accuracy, rigidity and stability as the most accurate method of precision alignment.

Levalators

Improving large, precision and long bed machinery performance

Farrat Levalators improve large, precision and long bed machinery performance by increasing alignment accuracy, rigidity and stability as the most accurate method of precision alignment.

Large machines generally need good foundations both to reinforce the machine bed and to reduce vibration by mass damping. Farrat Levalators are the vital connection between machine and foundation enabling machine and foundation to become one unit. A machine on weak supports may as well not have a foundation.

They can be fully grouted in, thus achieving a virtually built-in or encastré support which considerably increases the stiffness of the machine base and creates a complete machine foundation integration.

Farrat Levalator Range

Farrat Levalators overcome all the deficiencies of jackscrew support. Jackscrews are generally inadequate for large machine support as they are only virtually pivot supports and are therefore not stiff enough either horizontally or vertically. They distort under excessive loads thus limiting hold down bolt tension and create localised stressing in both machine bed and support plate.

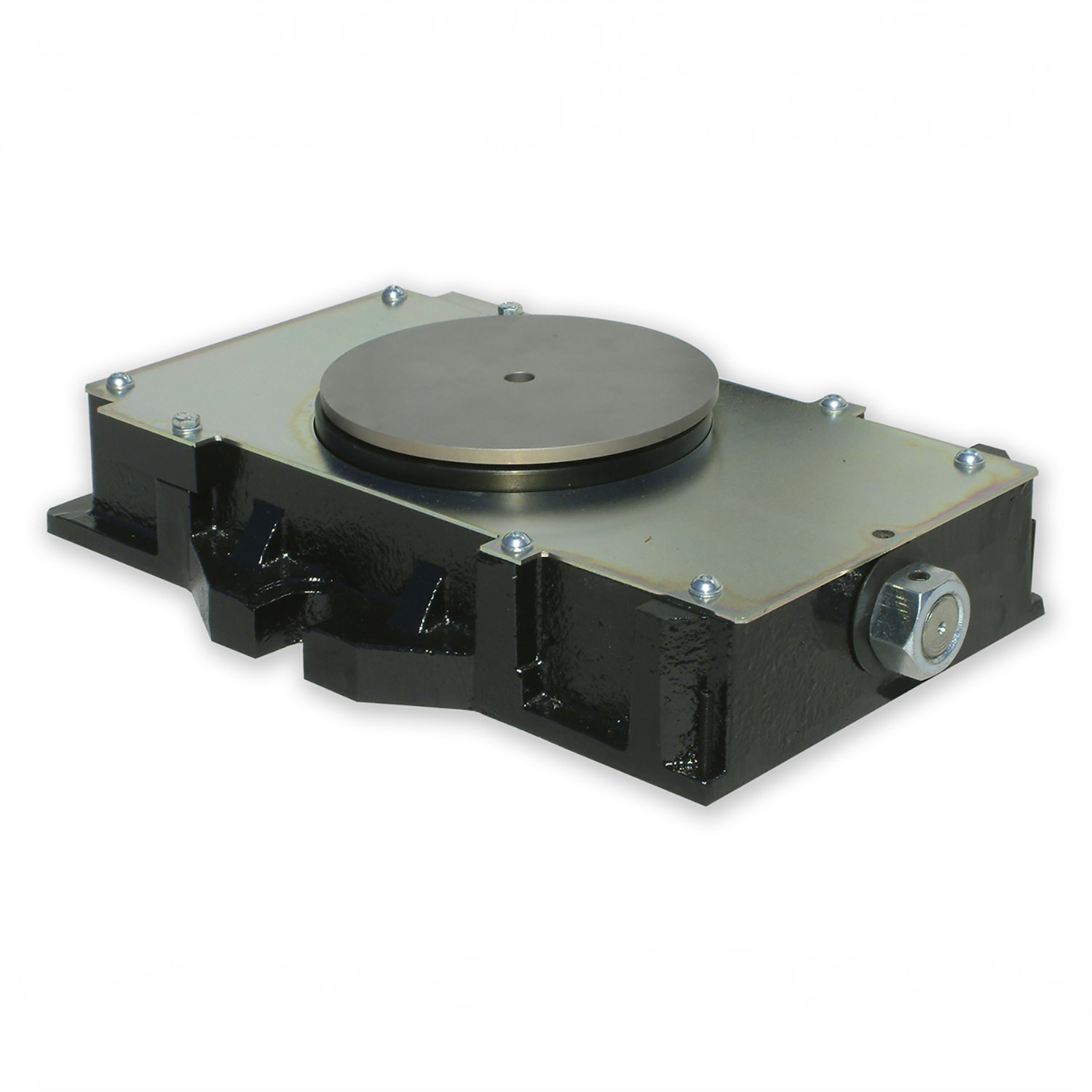

- Our Levalators consist of a high grade cast iron basebox machined on the inside to support the screw driven fully machined lower wedge (high grade cast iron) which in turn elevates the fully machined steel top wedge.

- A fully machined spherical disc sits in a spherical recess on the top surface of the steel wedge providing a spherical seating to correct misalignment and complex angles between machine and foundation.

- Auxiliary levelling screws in the basebox enable Levalators to be aligned in installations where Levalators are pre grouted prior to machine installation.

Precision Levalator Mounts

| Max Ultimate Load per unit* (kN) | Max Share of Machine Weight (kN) | Max Lifting Capacity (kN) | Specific Adjustment Torque (Nm/10kN) | Maximum Adjustment Torque (mm) |

Height Adjustment per full turn (mm) |

Vertical Stiffness (N/µm) |

|

|---|---|---|---|---|---|---|---|

| LA4 | 240 | 40 | 80 | 4 | 100 | 0.40 | 2500 |

| LA8 | 400 | 80 | 160 | 7.7 | 115 | 0.25 | 6500 |

| LA16 | 600 | 160 | 200 | 8.9 | 200 | 0.25 | 8000 |

*Max ultimate load made up of: Machine + Workpiece + Bolt Tension + Moment + Dynamic Forces

| Ref | L (mm) | L1 (mm) | L2 (mm) | B1 (mm) | B2 (mm) | B3 (mm) | W (mm) | H-mid (mm) | H-min (mm) | H-max (mm) | Adjustment (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA4 | 247 | 119 | 128 | 156 | 135 | 128 | 18 | 75 | 69 | 81 | +6.0 |

| LA8 | 305 | 145 | 160 | 210 | 185 | 170 | 23 | 82 | 76 | 88 | +6.0 |

| LA16 | 370 | 180 | 190 | 260 | 230 | 210 | 26 | 84 | 78 | 90 | +6.5 |

Features & Benefits

- Precision alignment for machines

- Rigid support for maximum machine bed stiffness

- Total machine-to-foundation integration

- Low overall height to ensure a low machine centre of gravity

- Systemised and predictable precision machine installation

- Precision adjustment to obtain very fine alignment

- High bolt tensions without bed distortion

- Micro-meter type height adjustment range of 12mm

- Facility to carry out subsequent alignment readjustments

- For machines with significant changes in load distribution

- No horizontal forces applied when adjusting

- High ratio of lifting force to adjustment torque

- Developed and manufactured in the UK by Farrat

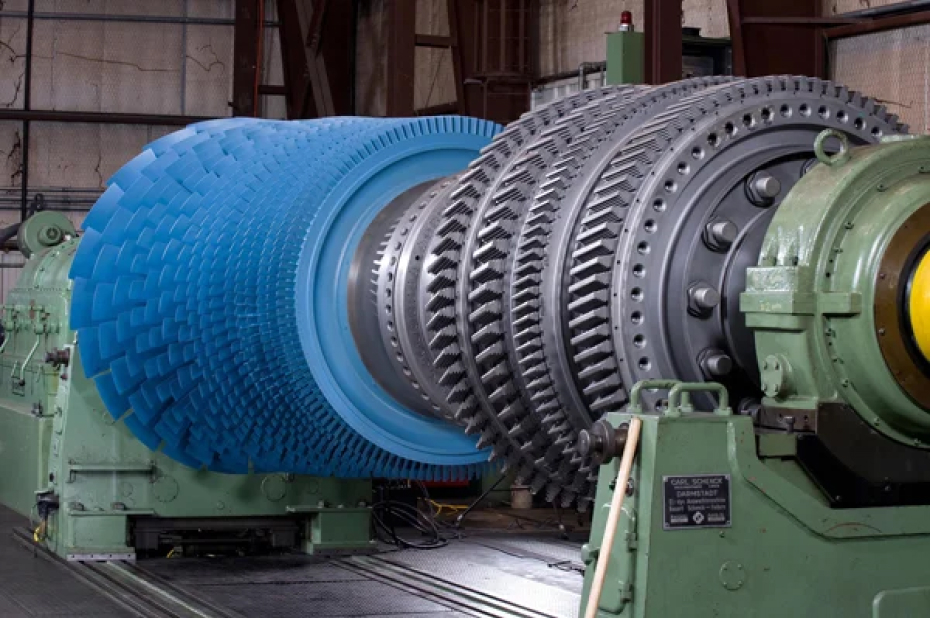

Machinery Applications

Long Bed machine tools, Roll Grinders, Lathes Plano-millers and Grinders, Machining centres, Turbomachinery, Steam Turbines, Gas Turbines, Rolling Mills and Large Process machinery.

Contact us

Please select the best route to suit your requirements. Whether you require technical help or you’d like to make a general enquiry. The team are here and always ready to support you.

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00