Voith Paper, a division of Voith GMbH, is a leading supplier in the international paper industry supporting all aspects of the paper-making process from fibres to end products. The company has global revenues in excess of Û1.7 billion and one third of global paper production is performed on Voith Paper production systems.

Voith was keen to move and install a very large reconditioned Waldrich Siegen roll grinder from Korea to Voith Paper in Manchester – the main purpose of this unit would be to grind paper machine rolls for one of the world’s largest paper mills. As the client was initially unsure if vibration isolation was required, Farrat suggested Univib undertake a survey which verified that there were low levels of vibration in the ground.

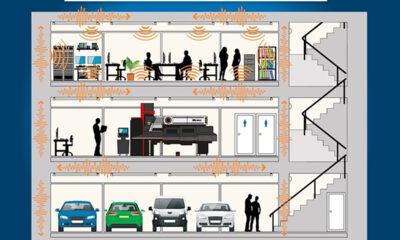

Whilst the actual vibration levels were low it was decided that it would be worth investing in a 7Hz vibration control system as a precautionary measure in case of vibrations from overhead cranes, future developments and adverse impacts from dropping components.