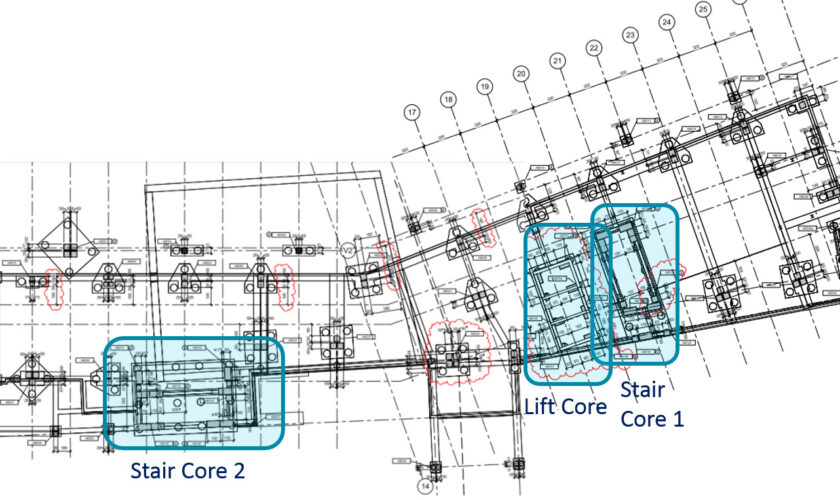

This was then followed by a coordinated process between Farrat and BDP to finalise the design and layout of the core vertical and lateral isolation systems as well as the structural design of the pile caps and isolated raft slabs.

For the lift core, which was set at a lower level, where access was restricted once the upper isolated slab was cast, Farrat provided an Isomat Acoustic Floating Floor system to be constructed between the bearings to enable a flat slab to be cast where no access was feasible thereafter.

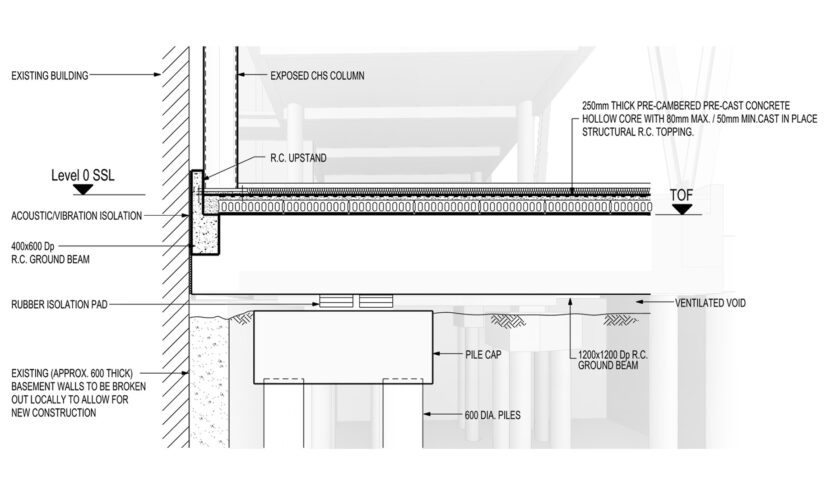

The majority of the subterranean outer perimeter of the building was in contact with existing, rigid structures either where ground beams were cast up against them or where the ground was back-filled up against it. In order to maintain the isolation performance of the building, Farrat’s Isofoam perimeter isolation material was used as a resilient acoustic barrier.

In total Farrat manufactured and supplied 113 Natural Rubber Laminated Acoustic bearings each with a natural frequencyof 8Hz at working loads.

Every bearing was designed, manufactured and tested up to full SLS load and in accordance with the applicable standard for building isolation bearings BS EN 1337-3 and a test certificate was issued for each bearing. Schedules were provided identifying which bearing, shear key or lateral restraint assembly was to be placed in each location.

Farrat supplied galvanised steel levelling plates and upper formwork plates enabling the pile caps to be cast with a ±35mm tolerance. Once the bearings were in position they were grouted using a high flow, non-shrink cementitious grout. The high capacity lateral restraint shear keys were also installed in the cores in the same way.

This process enabled Bouygues to construct the bearing installation into the flowing construction process, working from one end of the building to another with pile caps still being cast at one end whilst at the other the pre-cast ground floor was already being installed. Farrat visited the site once per week during the construction process to undertake detailed inspections as well as provide support and advice to the site team.