A Structural Thermal Break material designed to maintain structural integrity in the event of fire

STRUKTRA™ TBF

STRUKTRA™ TBF

Structural Thermal Breaks

STRUKTRA™ TBF is proven to have high compressive strength at a high temperature and low thermal conductivity, allowing designers to meet multiple building regulations relating to fire, heat loss and energy performance with the one structural thermal break product.

STRUKTRA™ TBF has been independently fire tested and verified to the following industry standards:

- A2,s1,d0 Fire-rated classification to EN 13501-1.

- Maintains very high structural performance and compressive strength to 500°C under EN ISO 604.

- Compliant for use under Document B Building Regulations for buildings above 11m.

Why choose STRUKTRA™

Structural Thermal Breaks?

Changes in Legislation in response to climate change and energy saving, has meant that reducing energy loss and the risk of condensation has grown in importance - as has the construction industries' preference for Farrat Structural Thermal Breaks.

Structural applications

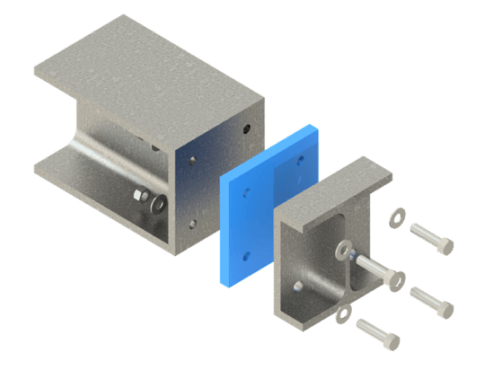

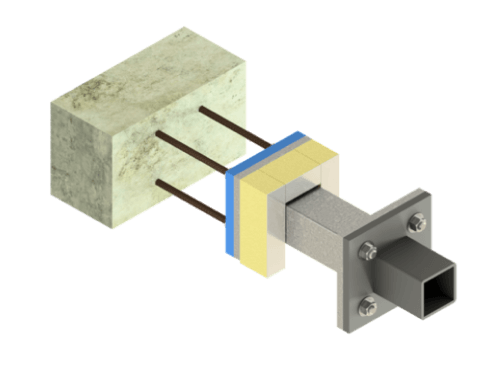

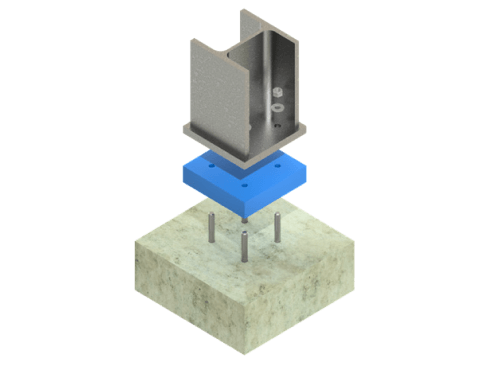

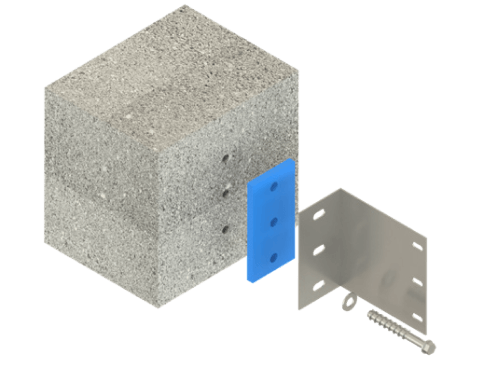

Farrat Structural Thermal Breaks are high performance thermal insolators used between horizontal and vertical connections of internal and external elements to prevent thermal or cold bridging.

STRUKTRA™ TBF can be used in a wide variety of applications where there is a structural requirement for thermal insolation:

STRUKTRA™ TBF is capable of transferring load in moment and shear connections without creating significant rotation.

STRUKTRA™ TBF can be used in anywhere a penetration or transition exists in a building envelope to improve building performance. Examples include:

- Structural frames

- Facade system connections to primary frames

- Connection of external to internal primary building elements

- Balconies

- Staircases

- Isolation of sub-structure and basement elements

- Man-safe systems

- Connections to existing structures

- Roof plant enclosures - columns

- Roof parapets

Testing

Independent material testing was undertaken in Germany by an Institute with DAkks Certification.

| Properties | Test standard | Title |

|---|---|---|

| Compressive Strength | EN 826 | Thermal insulating products for building applications. Determination of compression behavior. |

| Elastic Modulus | EN 826 | Thermal insulating products for building applications. Determination of compression behavior. |

| Thermal Conductivity | EN 12667 | Thermal performance of building materials and products. Determination of thermal resistance by means of guarded hot plate and heat flow meter methods. Products of high and medium thermal resistance. |

| Density | EN 1602 | Thermal insulating products for building applications. Determination of apparent density. |

| Water Absorption | EN 12087 | Thermal insulating products for building applications. Determination of long term water absorption by immersion. |

| Long Term Creep | EN 1606 | Thermal insulating products for building applications. Determination of compressive creep. |

Material properties

| Properties | Farrat TBK | Notes | |

|---|---|---|---|

| Compressive strength | Characteristic ƒck | 355 MPa | BS EN 1990 Equation (D.1) |

| Design ƒcd | 284 MPa | BS EN 1993-1-8 (YM2 = 1.25) (UK NA) | |

| Elastic modulus | 5326 MPa | ||

| Thermal conductivity / Resistance | 0.200 W/mK | ||

| Density | 2160 kg/m3 | ||

| Water Absorption | 0.40% | ||

| Long term creep | 20% | % Increase of initial strain (Serviceability Limit State) | |

Availability

| Thickness | Tolerance | Max Sheet Size |

|---|---|---|

| 5 mm | +/-0.6 mm | 1190×1000 mm |

| 10 mm | +/-1.0 mm | |

| 15 mm | +/-1.5 mm | |

| 20 mm | +/-2.0 mm | |

| 25 mm | +/-2.5 mm |

Orders & manufacturing

STRUKTRA™ Farrat’s structural thermal breaks are manufactured to your specific requirements. You send us your drawings and we manufacture them under strict BBA quality control. Depending on quantity, delivery can be next day or usually within 3 working days of order placement.

A fully dimensioned drawing for each plate with a clear project reference is usually required prior to manufacture.

Ensuring that you receive the correct product in time for your installation is an integral part of our service offering and is embedded in our BBA mark as well as ISO 9001:2015 and ISO14001:2015 certifications. This includes:

- Checking the drawings against the quotation and customer order

- 4-eyes check of the CNC programme

- Visual and dimensional inspection of the manufactured products

- Each item is then labelled individually so that it can be easily identified on site and traceability back to the manufacturer of the raw material is guaranteed.

Quotation Guidance

To enable us to give you the most efficient Thermal Break quote and to ensure it’s right the first time, we need to know a few things from you.

Please take a moment to watch this short video:

UK & International Enquiries

Farrat Isolevel Ltd, Balmoral Road, Altrincham, Greater Manchester, WA15 8HJ, United Kingdom.

Telephone: +44 161 924 1600

Email: [email protected]

Monday – Thursday: 08:30 to 17:00

Friday: 08:30 to 16:00