To support a better world

Even our workwear is made from recycled plastic bottles.

Even our workwear is made from recycled plastic bottles.

Farrat are engineers on a mission to support a better world, and as such, we look to reduce our negative impact on the environment and find new ways to increase efficiency and cut waste.

We do this by:

Farrat is proud to announce that our STRUKTRA™ TBK Structural Thermal Break has received an Environmental Product Declaration (EPD) in accordance with ISO 14025:2006 and EN 15804:2012+A2:2019/AC:2021.This certification was awarded by The International EPD System and underscores our commitment to transparency, sustainability, and environmentally responsible construction practices.

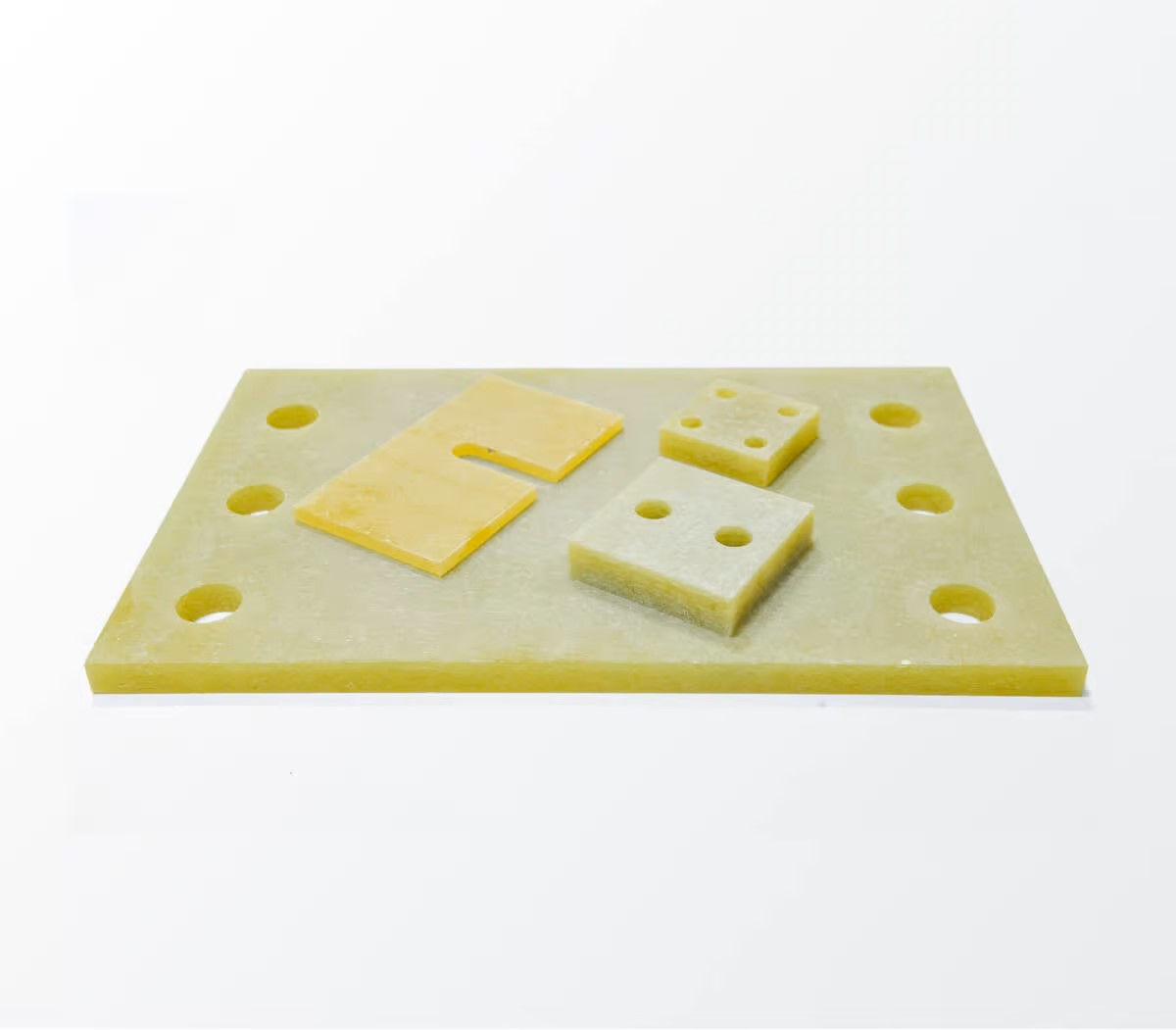

The EPD provides verified, third-party lifecycle assessment data, ensuring that architects, engineers, and builders have accurate environmental impact information when selecting materials for energy-efficient building designs. STRUKTRA™ TBK Structural Thermal Break is engineered to reduce thermal bridging in structural connections, improving insulation performance and contributing to lower energy consumption in buildings.

“With this EPD certification, we reaffirm our dedication to sustainable construction by providing a product that not only enhances thermal performance but also meets stringent environmental standards. As the industry moves towards greener building practices, we are committed to delivering solutions that support energy efficiency and carbon reduction goals”

– Amarachi Obilor, Application Engineer at Farrat

The STRUKTRA™ TBK Structural Thermal Break is a high-performance, durable material designed to improve the thermal efficiency of steel, concrete, and façade connections. By minimising heat transfer, it helps buildings meet increasingly stringent energy codes and sustainability certifications, such as LEED, BREEAM, and Passive House standards.

With this latest EPD certification, Farrat continues in developing innovative, environmentally friendly building materials that support a more sustainable future.

We have have been officially awarded an Environmental Product Declaration (EPD) for our Hybrid and Laminated Bearings, marking a significant milestone in the company’s commitment to sustainability and responsible manufacturing.

The EPD, which is independently verified and based on a comprehensive Lifecycle Assessment (LCA), provides a transparent and science-backed evaluation of the environmental impact of Farrat Hybrid Bearings. This certification reinforces the company’s dedication to developing high-performance engineering solutions that align with sustainable construction and infrastructure goals.

Farrat Hybrid Bearings are designed for superior vibration isolation, structural resilience, and longevity, making them essential components in construction, rail, energy, and industrial applications. The newly awarded EPD confirms key sustainability advantages, including:

The EPD certification further strengthens Farrat’s position as a trusted partner for sustainable engineering solutions, helping industries make informed procurement decisions based on verified environmental data.

For more information about Farrat Hybrid Bearings and the EPD certification, please visit:

We have taken a number of steps to reduce the amount of power that we use. We actually generate quite a lot of our own using natural resources. The roof of our offices in Altrincham are covered with solar panels, and since 2013 they have produced circa 15,000 kWh per year that we are able to use on site.

Our work on developing structural thermal breaks to reduce heat loss through building envelopes is well documented. and includes finer structural details such as façade system supports, balcony attachments, data centre substructures, and rooftop plant installations.

The ISO is an independent, non-governmental membership organization and the world’s largest developer of voluntary International Standards.

The ISO14001 standard provides practical tools for companies looking to manage their environmental responsibilities. Using ISO 14001:2015 can provide assurance to company management and employees as well as external stakeholders that environmental impact is being measured and improved.

We have a new energy monitoring system which allows us to monitor energy flowing to all of our manufacturing equipment.

We have adopted Industry 4.0 standards in digitising our documentation, so paper is only ever used when there is no other option. And when we do it is either recycled or FSC sourced.

We recycle and filter the water used on our waterjet cutting equipment.

Solar panels installed in 2013

Contact us now for an initial consultation.