The award-winning £7 million project at Nottingham Trent University’s Clifton campus involved the creation of inspiring state-of-the-art teaching and learning facilities.

Nottingham Trent University

Project Overview

The Challenge

To install a suitable structural thermal break system in precast concrete coffered units in the factory to simplify construction on site and providing the benefits of off-site construction.

The Solution

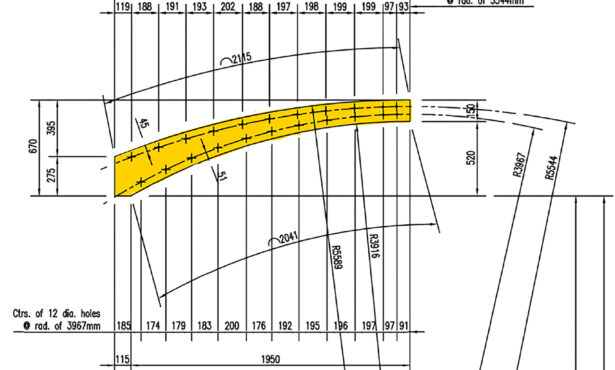

In total, Farrat supplied 56 Structural Thermal Break segments for the manufacture of 28 coffered precast concrete units. The ability to manufacture from sheet material provided the flexibility to install and create concrete units of a shape and size that would not typically suit proprietary mechanical thermal break systems.

The manufacturing CNC process used by Farrat produced very accurate Structural Thermal Break plates and our Technical Team worked with Evans Concrete in the early stages of the design process.

Farrat Structural Thermal Break plates were installed during the castings process in the factory allowing the complete unit to be erected in a single operation, incorporating the thermal break within the façade junction. Thermal modelling was undertaken to understand both the overall energy loss and to ensure that condensation would not be a problem.

Related Projects

Challenge our engineers

Contact us now for an initial consultation.